News, tips, views and research on the composting of packaging in Australia.

Composting your packaging

In Australia, compostable packaging is a new and growing industry, however there seems to be a lot of confusion about whether PLA coated packaging can be composted or recycled. And many claims in the media that no paper cups are recycled in Australia, is simply not true. ‘The bioplastic lining on PLA products dissolves during the repulping process and is easier to recycle compared to PE plastic coated cups’. This fact was recently verified by Planet Ark and The Australian Packaging Covenant. Some recyclers say they will not accept paper cups as they are unable to separate the plastic from the paper fibres, yet these very same companies accept paper milk and juice cartons which are made from the same components as coffee cups—plastic coated paper board.

Additionally, some Councils in Australia are taking certified Home Compostable packaging in the green waste collection*. (*Please check your local Council to see if this is the case in your area).

What’s PLA?

What’s PLA? Everything you need to know about Polylactic-acid (a cornstarch derivative).

So, where can I compost or recycle my packaging after use?

Click the button below and enter your location to find the closest facility near you!

What do the composting logos mean?

Home composting

The Home Compostable Verification logo clearly identifies and differentiates packaging materials as biodegradable and compostable in Australia and New Zealand only. To be certified compostable and carry the Home Compostable Verification logo, suitable biopolymer materials must undergo a stringent test regime outlined by AS 5810-2010 and carried out by recognised independent accredited laboratories to the Australian Standard AS 5810-2010. The Home Compostable Verification logo is a symbol that the product’s claims of biodegradability and compostability as per AS 5810-2010 has been verified.

Commercial composting

The seedling logo clearly identifies and differentiates packaging materials as biodegradable and compostable. To be certified compostable and carry the seedling logo, suitable biopolymer materials must undergo a stringent test regime outlined by AS4736 and carried out by recognised independent accredited laboratories to the AS4736 standard. The seedling logo is a symbol that the product’s claims of biodegradability and compostability as per AS4736 has been verified.

Composting Cellophane Bags

Both NatureFlex™ and Standard Cellophane bags can be composted at home. We tried it ourselves and you can already see the results after only two weeks in a backyard compost!

NatureFlex™ Bags

NatureFlex™ is a home compostable film originally developed by Futamura Group, Japan. Our NatureFlex™ bags are made in Australia from renewable cellulose fibre. They are certified home compostable by Australian Standards AS 5810. These bags have good moisture barrier for foods, and are heat sealable with a standard heat sealer. Can store food for up to 18 months under dry conditions without breaking down. Decomposition time approximately 15 weeks once in the elements.

Standard Cellophane Bags

Industrially compostable. Made in Australia from renewable cellulose film with synthetic moisture barrier. Can store food for up to 2 years under dry conditions. Can be heat sealed using standard heat sealer. Great for teas, cookies, biscuits. Standard thickness 23NK. Can be used in the freezer for food storage at -18 degrees. Biodegradable, but best suited to industrial composting facilities after use. Can be composted at home, however ideally composted in an industrial facility.

Decomposition of a NatureFlex™ Cellophane Bag & Standard Cellophane Bag after only two weeks in a backyard compost.

What are bioplastics?

Bioplastics

Bioplastics such as PLA (poly-lactic-acid) and PSM (plant-starch-material) are plastics derived from renewable biomass sources, such as vegetable fats and oils, corn starch, or microbiota. Bioplastics are usually derived from sugar derivatives, including starch, cellulose, and lactic acid. These can be used in the same way as conventional plastics, but are biodegradable and will break down under favourable conditions. Products made with bio-plastics produce less carbon emissions than those made with conventional plastics.

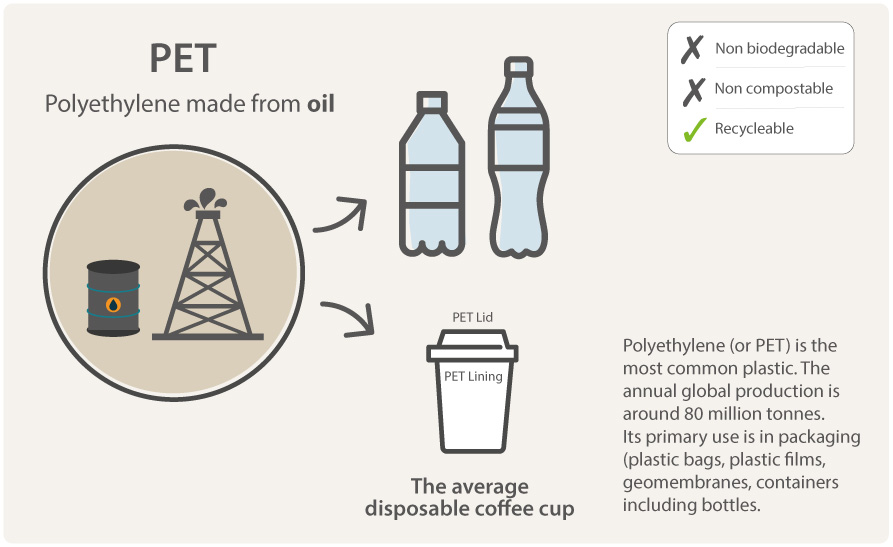

Conventional plastics

Such as PET are made from fossil-fuel plastics (also called petro-based polymers), and are derived from petroleum or natural gas. Production of such plastics tends to require more fossil fuels and to produce more greenhouse gases than the production of bio-based polymers (bioplastics). Petroleum based plastics take many decades to decompose, and as they break down, break up into smaller and smaller particles, getting into our waterways, are ingested by marine life, plants, and can enter our bodies via the food chain.

Please consider the environment before buying any single-use packaging.